Introduction to Optical Instrument Calibration

Optical instrument calibration is a fundamental process to ensure the accuracy and reliability of equipment used in scientific research, manufacturing, and quality assurance. Calibration involves setting or correcting an instrument to have a known relationship to a reference standard. This process is vital wherever optical measurements are critical, from the production floor of a high-tech factory to field measurements in environmental science.

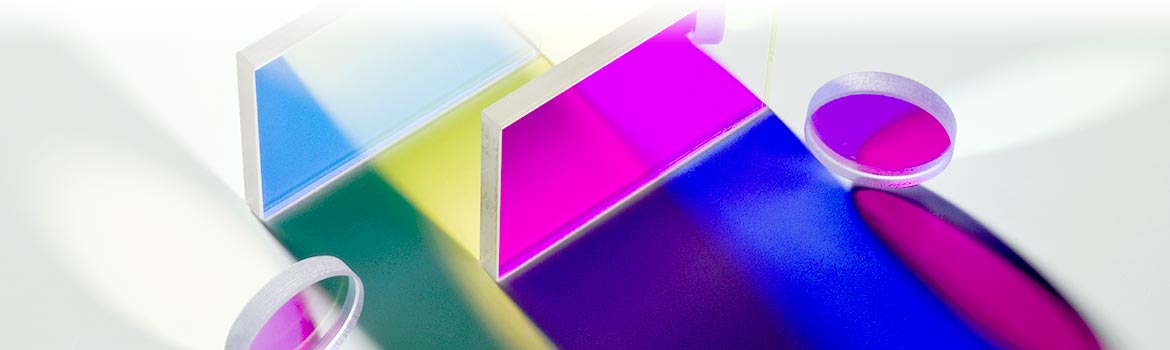

Optical filters are used strategically in calibration to control and manipulate the light entering the instrument, thus facilitating precise measurements. Whether attenuating specific wavelengths, selecting a range for transmission, or blocking unwanted light, optical filters can significantly affect the calibration of imaging systems, spectrometers, and various types of sensors.

Let's delve into the various optical filter types and how they are utilized in the calibration of optical instruments to bring about unmatched measurement fidelity.

Dichroic Filters: Spectral Control for Standardization

Dichroic filters offer high precision light modulation in a variety of calibration applications:

● Beam Steering: Used to reflect certain wavelengths precisely at specific angles, dichroic filters are essential for aligning optical paths during the calibration of imaging systems, ensuring that the light is directed accurately through lenses and onto sensors.

● Spectral Isolation: For the calibration of instruments requiring a narrow spectral band, dichroic filters can ensure that only those precise wavelengths are measured, cutting out any potential interference from neighboring wavelengths.

Dichroic filters serve the exacting needs of calibration, ensuring that light is controlled with specificity and accuracy.

IR Filters: Calibration in the Infrared Spectrum

IR filters find their application in the calibration of instruments dedicated to infrared measurements:

● Thermal Imaging Calibration: IR filters allow instruments to be calibrated to different regions of the infrared spectrum, ensuring sensitivity and accuracy while measuring temperature or energy variations.

● Infrared Spectroscopy: Calibration for wavelength accuracy in infrared spectroscopy relies significantly on the selectivity provided by IR filters, allowing for reference comparisons that are tight and dependable.

IR filtration is fundamental for instruments where infrared plays a key role, ensuring that their metrics are precisely aligned with spectral standards.

Bandpass Filters: Achieving Wavelength Precision

Bandpass filters are particularly useful for calibrating instruments that must operate within a strict spectral window:

● Photometric Calibration: By transmitting a specific wavelength range and blocking others, bandpass filters ensure that light detectors accurately measure the intensity of light within the defined passband, critical for photometric systems.

● Monochromator Tuning: For instruments that need to select for or calibrate against particular emission or absorption lines, bandpass filters can validate that only the desired narrow band of wavelengths is utilized in the process.

The focused transmission provided by bandpass filters is essential for calibrating instruments to desired levels of spectral precision and isolation.

Polarizing Filters: Ensuring Angular Consistency

Polarizing filters are employed in calibration to validate and adjust light polarization:

● Polarimeter Calibration: Instruments that measure the polarization state of light rely on polarizing filters to calibrate against known polarization levels, confirming that measurements are both precise and repeatable.

● Optical System Alignment: Polarizing filters are also used to ensure that light is consistently polarized before it enters or as it exits the system, an important consideration for calibration in systems where polarization affects the measurements.

Fine-tuning the polarization state with filters is key for instruments that depend on angular light properties.

Conclusion: The Science of Light Meets Calibration Excellence

Calibration is the unsung hero of optical measurement, ensuring instruments perform at their peak, and optical filters are the tools that help achieve this excellence. By manipulating the spectral characteristics of light with precision filters, calibration transcends mere functionality—it becomes an assurance of accuracy, reliability, and trust in every measurement taken.

At KUPO Optics, our expertise in high-quality optical filters places us at the vanguard of providing the crucial components needed for stringent calibration processes. We stand by those who value precision measurements, offering filters that set the benchmark for accuracy in every optical instrument they touch. Choose KUPO Optics for your calibration needs, and instill confidence in every reading and resolution.