At KUPO Optics, we pride ourselves on our state-of-the-art manufacturing facility, specifically designed to meet the highest standards in optical filter production. Our commitment to excellence is evident in our expansive 2000 square meter cleanroom, which ensures an ultra-pure environment that is crucial for the flawless creation of our premium filters. This meticulous attention to environmental control virtually eliminates the risk of particle contamination, a common cause of coating failure in lesser quality filters.

Our production process is further enhanced by advanced coating chambers equipped with Ion Assistant Deposition (IAD) technology, ensuring that our filters boast uniform and durable coatings. We understand that precision is paramount in our industry, which is why every stage from cleaning to cutting and inspection is executed with meticulous care, utilizing the finest instruments and techniques available. We take great pride in delivering products that not only meet but exceed the rigorous demands of our customers.

Cleanroom

Our expansive 2000 square meter cleanroom is the cornerstone of KUPO Optics' ability to manufacture filters of the highest quality. Within this controlled environment, we meticulously manage air quality to prevent the tiniest of particles from affecting our filters. This is integral to ensuring the integrity and performance of our coatings and is a testament to our unwavering commitment to excellence.

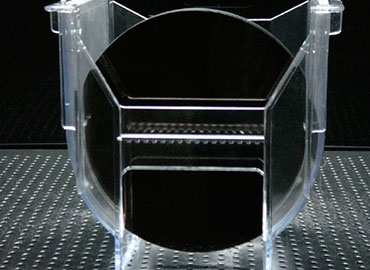

Coating Chambers

Our coating chambers, with dimensions of 1.7 meters in height and 1.5 meters in diameter, are equipped with the latest Ion Assistant Deposition (IAD) technology. This advanced process allows us to create coatings with exceptional density and attachment to glass substrates. The innovative design of the planetary rotating trays ensures uniform application, guaranteeing that each filter consistently meets our rigorous optical specifications.

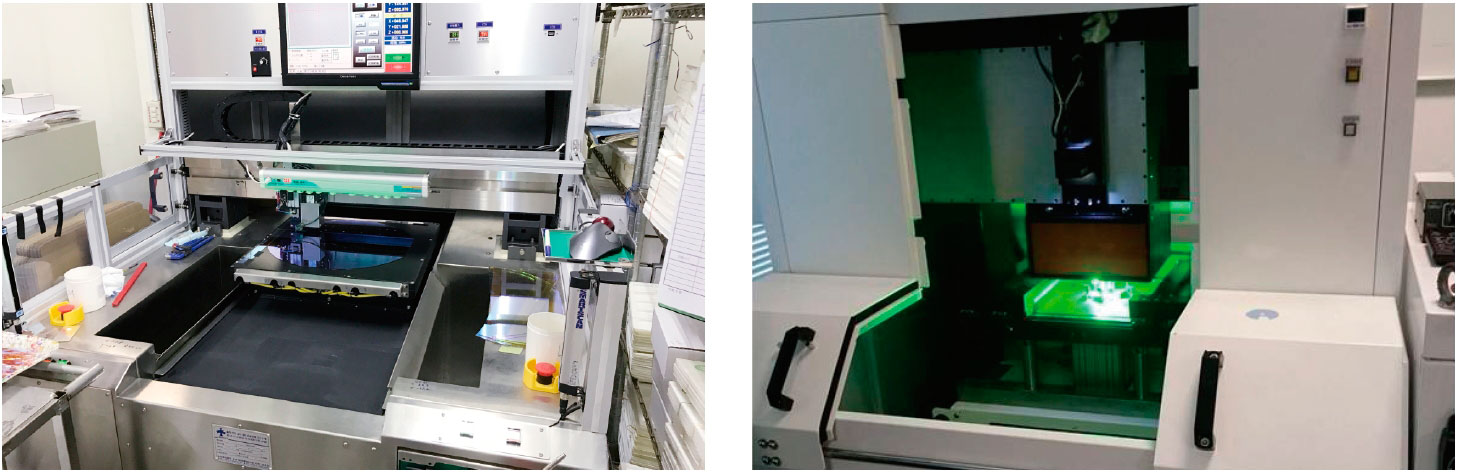

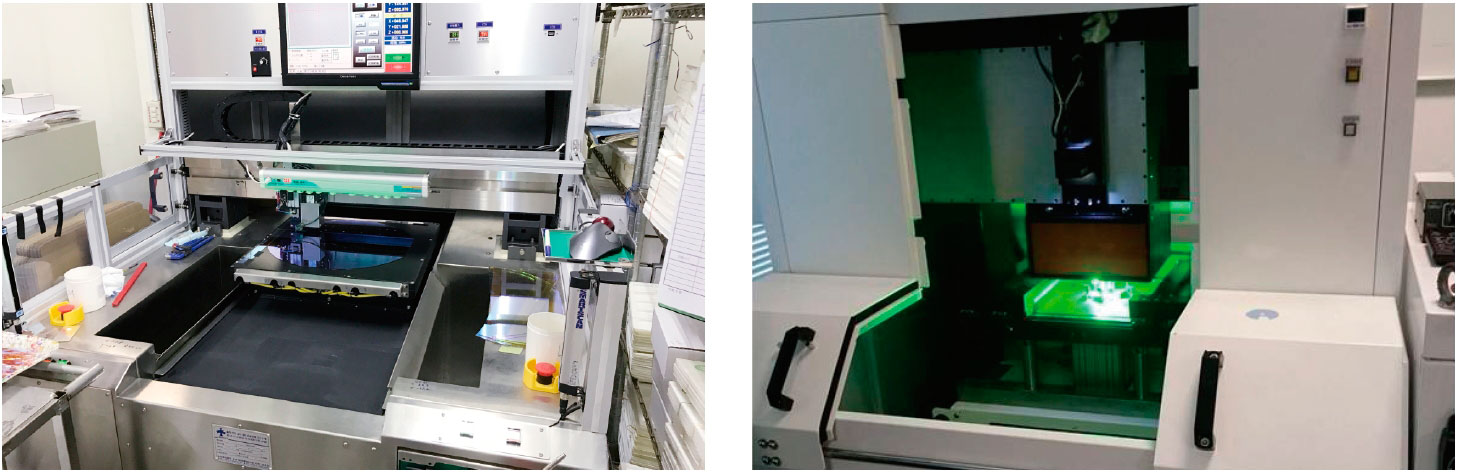

Cleaning

At KUPO Optics, we understand that cleanliness is paramount. Our ultrasonic cleaning machines thoroughly purify all substrates before the coating process. This crucial step ensures optimal adhesion and flawless surfaces, making sure that each filter is pristine upon delivery.

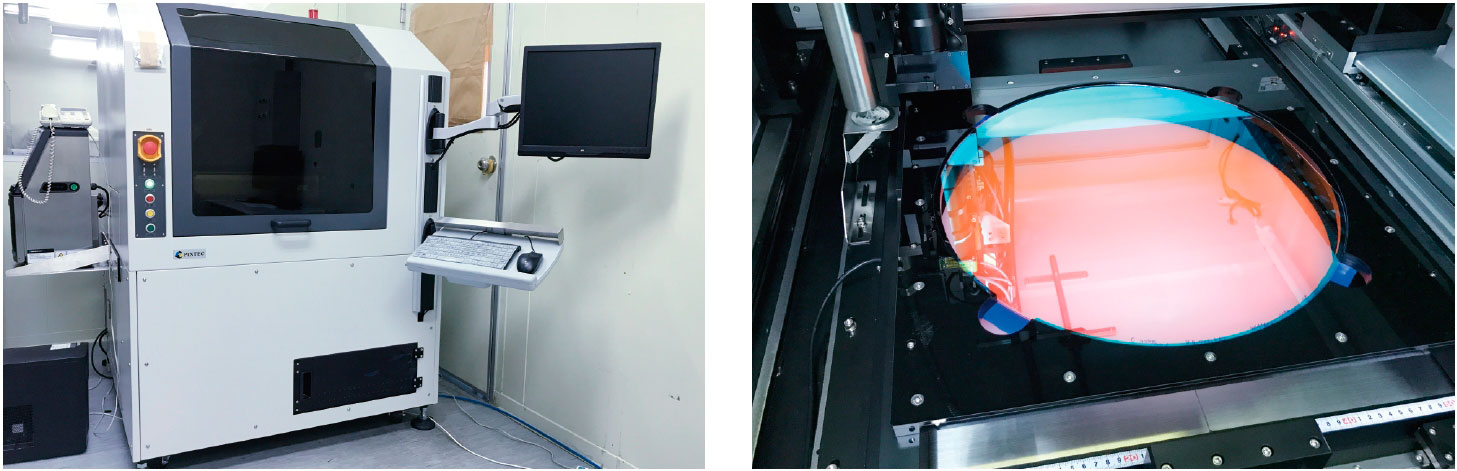

Cutting

With our highly precise linear and laser cutting capabilities, we can tailor our filters to any shape or size. Whether a project calls for custom designs or standard cuts, our technology allows us to craft filters from large 450mm diameter plates with exacting precision, meeting diverse and specific customer needs.

Spectrometer

Quality assurance is at the core of our production, and our spectrometers are central to this purpose. By meticulously scanning each coated filter, we ensure that every product aligns with the required optical specifications. This double-check system, both before stocking and again prior to shipment, reinforces our commitment to delivering impeccably accurate filters.

Surface Inspection

Our meticulous surface inspection protocols are a reflection of our dedication to perfection. Utilizing sophisticated inspection instruments, we identify and eliminate any filter that does not meet our stringent scratch and dig criteria. Ensuring that every filter delivered meets high surface quality specifications is just one way we uphold our promise of excellence to our customers.

KUPO Optics focuses on providing the highest quality in each filter we produce. Our world-class facility is a reflection of the care and detail found in our products, setting new standards in the optical filter industry.